The Uniqueness of Welding Technology

What is welding? Welding can be defined as joining the two pieces or more metals to become one piece of metal through an action of heat or pressure, or both either by using a filler wire or not. Why do we need to know the very least basic skill of welding? Let’s imagine if we are in a situation of whereby a steel pipe is short, and we want to increase its length for specific application. To solve this matter, welding is a best choice. What is the advantage of knowing how to weld the steel? Simply because we can join the steel pipe by our own skills.

Then, why do we have to learn about welding metallurgy? Welding is a kind of heat treatment since welding process is about rapid heating and rapid cooling. Meaning that we heat the steel rapidly till it melts, and then rapidly cooled. This process certainly affects the microstructure at the area not only the melted area, but also its nearby area so-called heat affected zone. Albeit the good design by steel manufacturer in terms of its mechanical properties, the changes in microstructure during welding deteriorates the mechanical properties at the area. This deterioration can lead to the joining failure which then can be a cause for any in-service structure damage.

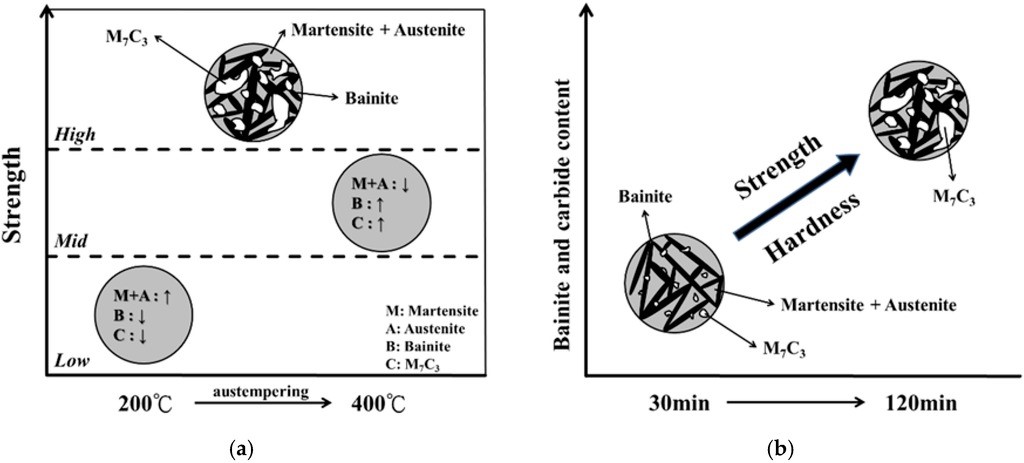

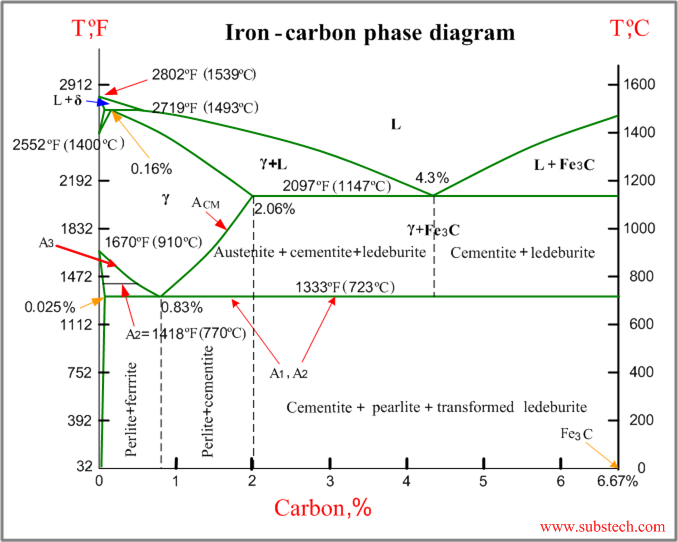

How does the microstructure changes affect the mechanical property of the steel. Steel is well known as a versatile material because it has different mechanical properties to meet with different the applications. The different in carbon content, alloying element and the thermal history during steel production results in different mechanical property of steel. The well control of these three parameters produces variety of steel to be used in industry such as ship making industry, oil and gas industry, tool making industry, automotive industry and so on. Controlling these parameters means controlling the microstructure and controlling the microstructure means controlling the intended mechanical property of the steel. Refer figure 1 for iron-carbon phase diagram and figure 2 for the relationship between microstructure and mechanical property.

Since welding is about heating the steel and cooling it, therefore controlling the thermal history during welding is also relates to controlling the microstructure of weld metal and its mechanical property. Thus, it is crucial to know the correct parameter setting of our welding machine to ensure the good joining with good mechanical properties that produced during welding.

Prepared by,

Ts. Dr. Sarizam Mamat

/seh2.jpg)

-Program./visit1.jpg)